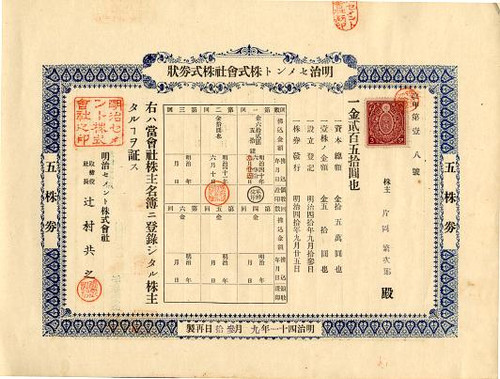

Beautifully engraved Certificate from the Japan Synthetic Rubber Company (JSR)issued in 1989. This historic document has an ornate border around it with a backprint of a munufacturing facility. This item has the printed signatures of the company's officers and is over 11 years old. 1957, Dec: In accordance with the special measures law passed by the Japanese government to commence domestic production of synthetic rubber, Japan Synthetic Rubber Co., Ltd. 1960, Apr: Operations began at the Yokkaichi Plant, with production and sales of Butadiene, SBR and SB latex. The Osaka Branch was opened. 1962, Jun: The Nagoya Branch was opened. Sales of High-styrene latex began. Jul: Sales of High-styrene rubber began. 1963, Jan: A carbon masterbatch plant was completed within the Yokkaichi Plant and production began. Jul: Sales of paper coating latex (PCL) began. 1964, May: After the 8th annual settlement of accounts, dividends to shareholders began. Oct: JSR advanced into the field of synthetic resins and production of ABS resin began within the Yokkaichi Plant. Nov: Sales of NBR began. 1965, Feb: Sales of BR began. 1966, Oct: CTPB (an adhesive for solid rocket fuel) was developed. 1967, May: Sales of ROADEX (asphalt pavement reinforcement) began. 1968, Apr: The Chiba Plant was completed, and production of butadiene began. Jul: The European Office was opened. 1969, Mar: Sales of IIR began. Apr: Changed company's status to private owned. 1970, Sep: Sales of EPDM began. 1971, Jan: The Kashima Plant was completed, and production of butadiene and SBR began. Aug: Stocks were listed on the First Section of both the Tokyo and Osaka Stock Exchanges. 1972, Dec: Sales of IR began. 1974, Jun: Sales of RB began. 1975, Apr: Sales of acrylic emulsion began. 1978, Feb: Production and sales of PCR (Pressure-sensitive Conductive Rubber) began. Sep: Sales of asphalt and spray emulsions began. 1979, Apr: Sales of CIR (negative type photoresist) began. JSR advanced into the electronic materials business. 1981 Apr: Sales of AES resin began. Jul: With the commencement of sales in IMMUTEX (uniform latex for clinical dianosis), JSR advanced into the medical field. 1982, May: Importation and sales of optical fiber coating materials began. Nov: Sales of PFR (positive type photoresist) and AFLAS (fluorocarbon elastomer) began. 1984, Apr: Sales of DESOLITE (optical fiber coating materials), SBS (thermoplastic elastomer) , resin began. Mighty Series (structural adhesive) began. 1985, May: Sales of SIS (Styrene Isoprene block Copolymer) began 1986, Mar: Nylon 46 was marketed. Sep: Sales of JENIX (EPDM / Silicone rubber blend) began. Dec: Sales of STADEX (size standard particles) began. 1988, Mar: Sales of OPTMER AL (Alignment films for LCDs) and OPTMER SS (protective coatings for LCDs) began. 1989, Apr: Two-day weekends and flexible working hours were introduced to the entire company. Under cooperative development with Sony Corp., the Solid Creation System, which makes 3D plastic models by using lasers and computers was developed, and sales began. May: Tsukuba Research Laboratory was officially opened. Oct: Japan's first plant specializing in TR(thermoplastic elastomer) production, SHELL JSR ELASTOMERS K.K.was completed within the Kashima Plant. Nov: Sales began on newly developed PCRs and ICs inspection systems. 1990, Feb: Concerning photoresists for Europe and North America, a joint venture contract was signed with UCB S.A. (Belgium). Mar: The senior employment system was introduced. Apr: A program initiating Equal Opportunity for female employees was introduced.The creative holiday system was introduced. ARTON (heat resistant transparent resins) was developed. Jun: The production method of crosslinked hollow particles was established, and the development of new markets was undertaken. 1991, May: CDs made from ARTON which create the realism of a live performance were developed. Jul: STADEX having a diameter of 0.1um received certification from NIST. Oct: Sales of DYNAFLOW and DYNACLIN (water soluble polymer) began. 1992, Jan: Childcare leave and healthcare leave systems were introduced. May: DYNARON (hydrogenated polymer) and DYNARON ALLOY (the thermoplastic elastomer using this polymer) were developed, and sales began. 1993, Jan: New research building was completed within the Yokkaichi Plant. Declared total abolishment of carbon tetrachloride in the production of latex. Apr: Sales of NANOMASTER (high concentration microsol generator) and FILTEX (standard particle dispersion liquid) began. May: Sales of Printed Circuit Board Testing Fixtures employing new type PCR began. Jul: UCB-JSR Electronics S.A. (Belgium) became wholly-owned subsidiary of JSR, and restarted by being renamed JSR ELECTRONICS N.V. Simultaneously JSR MICROELECTRONICS,INC. acquired U.S. operation as their subsidiary. 1994, Feb: ISO9002 certification were obtained for synthetic resin and NBR of the Yokkaichi Plant. Apr: Companywide PLP (Product Liability Prevention) system was established. Dec: The Shanghai Office was opened. Sales of OPTMER CR (color pigment dispersed resists for LCDs color filters) began. In order to conduct local production of CMB, capital investment was made in PI INDUSTRY LTD.(Thailand). 1995, Jul: The Seoul Office was opened. Aug: Commissioned Production Agreement of ABS resin was concluded with a resin manufacturer, GPCT (Thailand). Sep: ISO9002 certification was obtained for the opto-electronic materials of the Yokkaichi Plant. Nov: A high transfer blow molding technology (J-Blow) which gives excellent appearances equivalent to injection molding was developed. 1996, Feb: To establish a synthetic rubber producing company, BST Elastomers Co., Ltd. (Thailand) a joint venture business agreement was executed among BST Co., Ltd., Nippon Zeon Co., Ltd., JSR, etc. Jun: A microphotoresist manufacturing subsidiary, JSR Electronics Kyushu Co., Ltd.(Saga) was established. Sales of epoxy type photo-curing resin having high accuracy, high-performance for photofabrication (stereolithography) models.In Tianjin (China) a joint venture company, TIANJIN KUO CHENG JSR RUBBER INDUSTRY Co., Ltd. was established together with KUO CHENG INDUSTRIAL Co., Ltd. (Taiwan). Jul: The ABS resin business was integrated with that of the Mitsubishi Chemical Corp., and a joint venture company, Techno Polymer Co., Ltd. was established. 1997, Feb: JSREDSM Engineering Plastics Co., Ltd. a joint venture company between DSM Engineering Plastics B.V.(Holland) and JSR was established. Mar: Construction work was completed for photoresist plant of JSR MICROELECTRONICS, INC. Apr: Free Time System was introduced into the Research and Development Dept. New Mid-Term PlangJSR 21hstarted (from fiscal year '97 to fiscal year 2001). Oct : The Taiwan Office was opened. Completed a photoresist production plant of JSR Electronics Kyushu Co., Ltd. Nov : The Singapore Office was opened. ARTON Process Research Laboratory was officially opened. Dec : Changed of corporate name to "JSR Corporation." 1998, Mar : ISO14001 certification was obtained for the Yokkaichi Plant.

Japan Synthetic Rubber Company (JSR)

MSRP:

$19.95

$14.95

(You save

$5.00

)

- SKU:

- japsynrubcom

- Gift wrapping:

- Options available